- DE

- EN

Resource efficiency and a circular economy follow the same concept: only by taking into account the entire life cycle of a product, © VDI ZRE the negative impacts from raw material extraction, production, use and disposal for the environment and society can be reduced. The two concepts go side by side, with resource efficiency primarily aiming to reduce the use of materials and energy, while the circular economy provides strategies for closing material and energy cycles.

© VDI ZRE the negative impacts from raw material extraction, production, use and disposal for the environment and society can be reduced. The two concepts go side by side, with resource efficiency primarily aiming to reduce the use of materials and energy, while the circular economy provides strategies for closing material and energy cycles.

The circular economy serves to conserve natural resources and, taking into account the precautionary principle, is intended to protect both people and the environment in the production and management of waste.*

Bundestag der Bundesrepublik Deutschland (2020): Gesetz zur Förderung der Kreislaufwirtschaft und Sicherung der umweltverträglichen Bewirtschaftung von Abfällen vom 23.10.2020. §1 KrWG. (last reviewed on 03/11/2022)

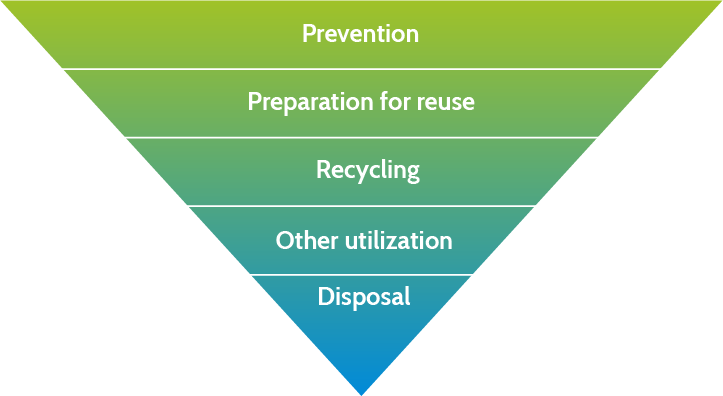

In particular, waste avoidance, preparation for reuse, and recycling promote raw material security and can reduce greenhouse gas emissions along the entire value chain. Waste prevention strategies, such as the zero-waste strategy, are in accordance with the waste hierarchy and are always preferable to recycling strategies, such as plastics recycling.

For the preparation for reuse as well as for recycling, the expenses for these strategies should not exceed the expenses for the production of products from the respective primary raw materials. The entire life cycle must therefore be included in the assessment so that, among other things, the recovery of recyclable materials and the use of recyclates actually lead to a reduction in greenhouse gas emissions. The evaluation of the resource input can be carried out by applying the VDI guideline series 4800 and the VDI guideline 4600.

Recyclables and recyclates are essential connecting elements in the circular economy, linking the beginning and the end of the value chain. Recyclables are extracted from the waste stream. These include, for example, used plastics, used paper, used metals or used glass, which can then be recycled further. Once the recycling process has been completed, the recyclables become so-called recyclates or secondary raw materials. They are available again for further value-added processes. For the production of recyclates or secondary raw materials, however, it is important to note that, according to § 5 of the German Closed Substance Cycle Waste Management Act, certain requirements must be met. These are determined by the definition of the end of waste characteristic*

Bundestag der Bundesrepublik Deutschland (2020): Gesetz zur Förderung der Kreislaufwirtschaft und Sicherung der umweltverträglichen Bewirtschaftung von Abfällen vom 23.10.2020. §5 KrWG. (last reviewed on 03/11/2022)

:

© AdobeStock / Animaflora PicsStockOnly when the above-mentioned requirements have been met are the recyclates or secondary raw materials no longer classified as waste and can be reintroduced into a value-added process. Furthermore: The purer the recyclables are for the recycling process, the higher the quality of the recyclates or secondary raw materials. This plays an important role for the renewed use in the value chain and thus for the economic efficiency.

© AdobeStock / Animaflora PicsStockOnly when the above-mentioned requirements have been met are the recyclates or secondary raw materials no longer classified as waste and can be reintroduced into a value-added process. Furthermore: The purer the recyclables are for the recycling process, the higher the quality of the recyclates or secondary raw materials. This plays an important role for the renewed use in the value chain and thus for the economic efficiency.

The treatment processes are divided into material (mechanical and feedstock) and energy recovery, whereby material recovery is always preferable to energy recovery in accordance with the waste hierarchy.

Material recycling is currently the focus of social and political attention and is to be promoted and expanded. The state of the art in materials recycling is advanced and enables recycling rates of 80 percent to over 90 percent, particularly for the common fractions glass, paper, metal and non-ferrous metals (including steel and aluminum). For the recycling of plastics, on the other hand, recycling rates are low. Although the mechanical recycling of plastics is technologically advanced, various challenges still need to be overcome in order to efficiently close the plastics cycle.*

https://www.vdi.de/news/detail/circular-economy-fuer-kunststoffe-neu-denken

For the recycling of batteries, too, there is still insufficient recycling capacity available for the volumes that will be generated for recovery in the future. Action is required here from all actors in the value chains in order to overcome the current challenges in terms of the goal of a circular economy.

The implementation of a circular economy in SMEs can be done by installing circular management strategies. There is a wide variety of circular management strategies through which SMEs can also benefit economically. A solid data basis is essential for the introduction of circular economy strategies. The material flows within the company can be determined by a material flow analysis. The data obtained can be used to establish successful material flow management through targeted optimisation. Based on this, circular economy strategies enable the avoidance of waste as well as the reuse and recycling of valuable materials, recyclates and secondary raw materials. Among the circular economy strategies are

Recycling strategies can be implemented both within and across companies. In particular, business cooperations promote the exchange of resources and knowledge on an inter-company level. One example is the networking of companies within industrial parks. In addition, numerous recycling initiatives offer companies the opportunity to participate in the development and use of new recycling technologies.

Get in touch for further information or help regarding the topic of "Circular Economy".

Tel.: +49 (0)30 2759506-505

E-Mail: zre-industrie@vdi.de