- DE

- EN

© Panthermedia / AppleEyesStudioWe encounter plastics in almost all areas of daily life. Thanks to their low weight, adaptable material properties and countless possible applications, plastics are popular materials. However, their production requires fossil raw materials that have to be extracted and processed at great expense.

© Panthermedia / AppleEyesStudioWe encounter plastics in almost all areas of daily life. Thanks to their low weight, adaptable material properties and countless possible applications, plastics are popular materials. However, their production requires fossil raw materials that have to be extracted and processed at great expense.

This gives rise to several questions: How can the use of fossil raw materials be kept as low as possible? Can fossil oil be substituted, if necessary? Is it possible to make the processing of plastics more resource-efficient in principle? And how can the disposal and recycling of raw materials be ensured - especially in view of the fact that more than 50 percent plastic waste is still recycled for energy (e.g. incinerated)?*

Conversio (2020): Kurzfassung der Conversion Studie - Stoffstrombild Kunststoffe in Deutschland 2019, p. 11.

In order to identify potentials for resource-saving plastics processing, comprehensive information, helpful tools as well as practical examples and videos on the topic can be found below.

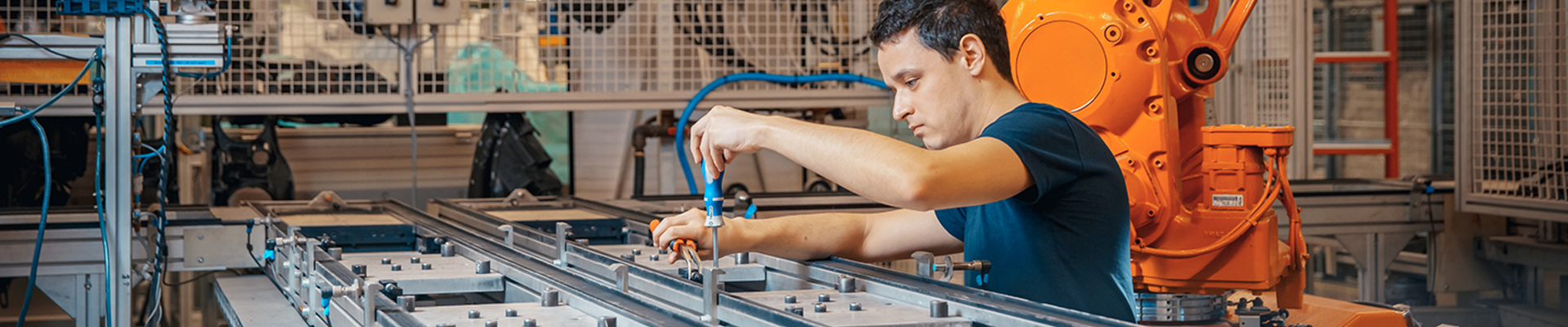

Working with metal takes place in many different areas and industries - including metal production, processing, mechanical engineering and vehicle construction. Metal production and the processing of the material have always been extremely resource-intensive. It is therefore even more important to use the available resources as efficiently as possible.

© Panthermedia / cookelmaThe technologies used in these sectors still offer significant potential for increasing material and energy efficiency. In order to identify and raise this potential, helpful information on the topic of metal processing, a wide range of online tools as well as practical examples and videos from the metal processing industry are summarised below.

© Panthermedia / cookelmaThe technologies used in these sectors still offer significant potential for increasing material and energy efficiency. In order to identify and raise this potential, helpful information on the topic of metal processing, a wide range of online tools as well as practical examples and videos from the metal processing industry are summarised below.

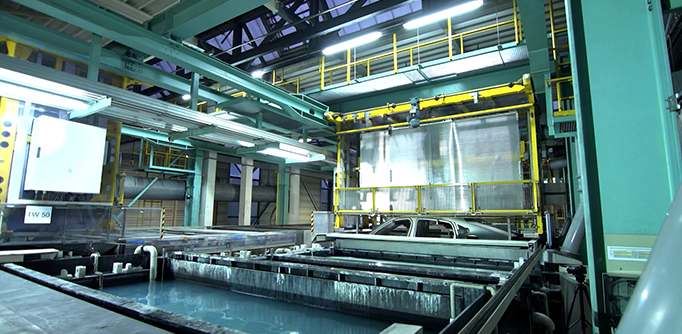

Adequate surface treatment is of great relevance for a large number of different materials. After all, this work step has a lasting influence on the service life of products. For this reason, surface finishing is one of the most important subsectors of the metalworking industry.

However, in contrast to this there is the material and energy input that is required for the upgrading of the diverse surfaces. In order to determine the points at which  © VDI ZREefficiency potentials arise in surface processing companies that keep additional material and energy input as low as possible, comprehensive information on the topic as well as helpful tools, illustrative practical examples and videos on the various areas of surface processing are compiled below.

© VDI ZREefficiency potentials arise in surface processing companies that keep additional material and energy input as low as possible, comprehensive information on the topic as well as helpful tools, illustrative practical examples and videos on the various areas of surface processing are compiled below.

Get in touch for further information or help regarding the topic of "Production Engineering".

Tel.: +49 (0)30 2759506-505

E-Mail: zre-industrie@vdi.de