- DE

- EN

The aim of the efficient use of natural resources is to decouple economic growth from resource consumption.*

Bundesministerium für Umwelt, Naturschutz, nukleare Sicherheit und Verbraucherschutz (2020): Programm zur nachhaltigen Nutzung und zum Schutz der natürlichen Ressourcen (online), accessed on 06/08/2022.

Decoupling these two factors not only contributes to sustainable economic growth, but at the same time helps to conserve resources and protect the climate.

However, resource efficiency is not only important from an ecological and social point of view, but is also economically relevant for companies in particular. Many companies are continuously finding new potential for implementing measures that help to increase their resource efficiency.

Resource efficiency therefore has a positive effect on both business success and the environment.

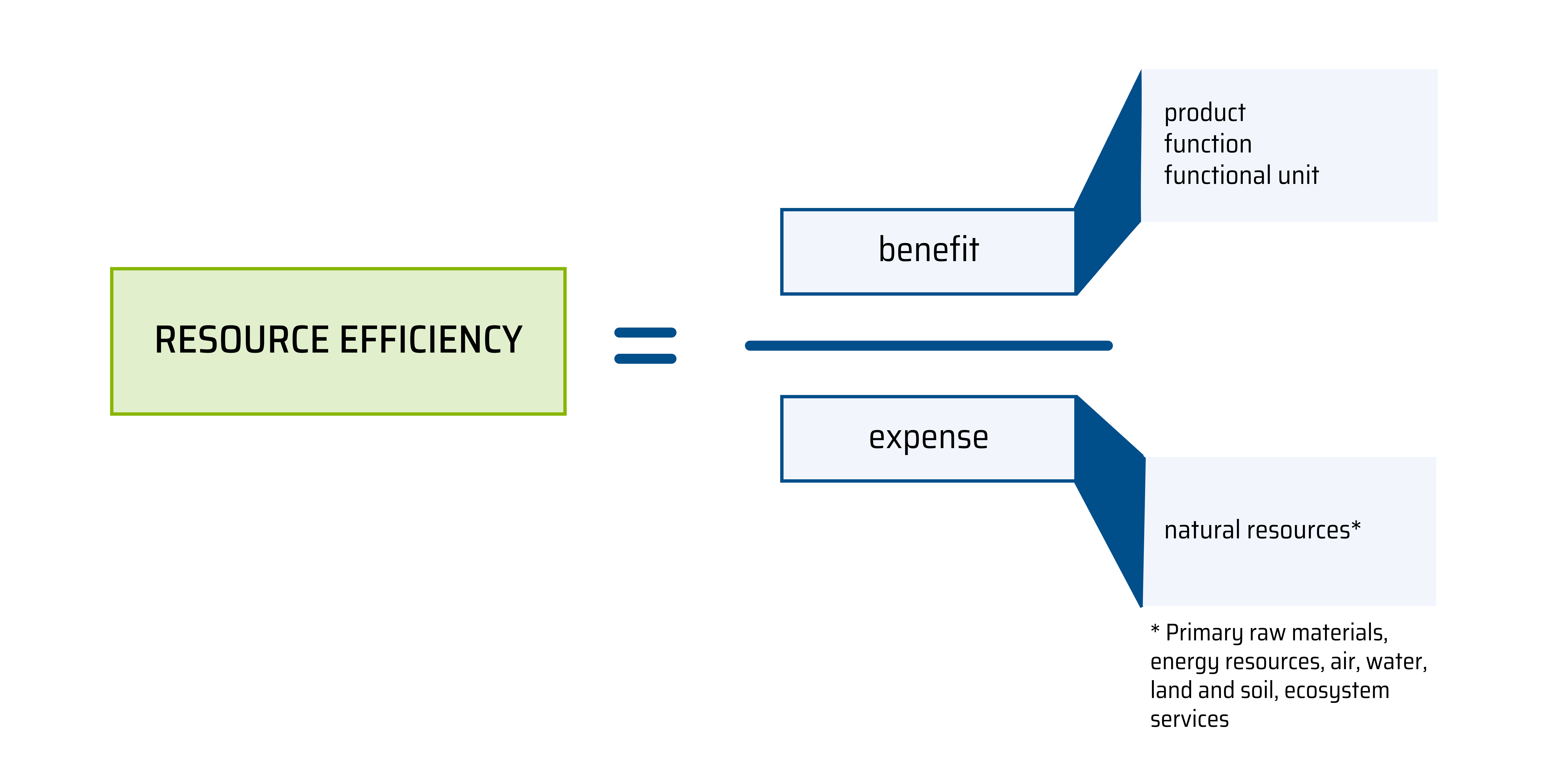

According to the guideline VDI 4800 part 1, resource efficiency (RE) is defined as "the relationship between a specific benefit or result and the deployment of resources required to achieve this".

© VDI ZRE (in Anlehnung an VDI 4800 Blatt 1)

© VDI ZRE (in Anlehnung an VDI 4800 Blatt 1)

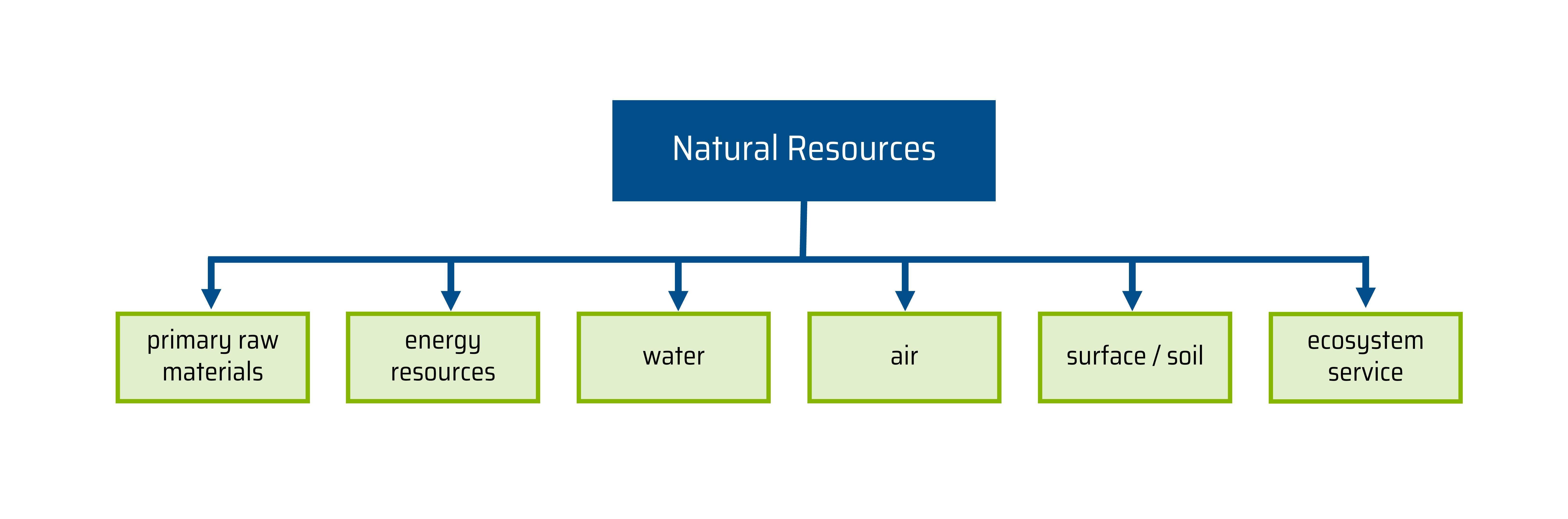

In the industrial environment, resources are defined as those items that are required and consumed for the production of goods and services. A distinction is made between technical and economic resources - such as personnel, operating resources, capital and knowledge - and natural resources.

In terms of resource efficiency, however, only natural resources are considered.

© VDI ZRE (in Anlehnung an VDI 4800 Blatt 1)

© VDI ZRE (in Anlehnung an VDI 4800 Blatt 1)

© VDI ZRE

© VDI ZRE

The majority of the world's raw material reserves are only available in limited quantities - regardless of whether they are energy resources or other primary raw materials. As a further consequence, resources that are consumed today will no longer be available for future generations. The economical and efficient use of limited resources therefore forms a key aspect on the way to a resource efficient economy and industry.

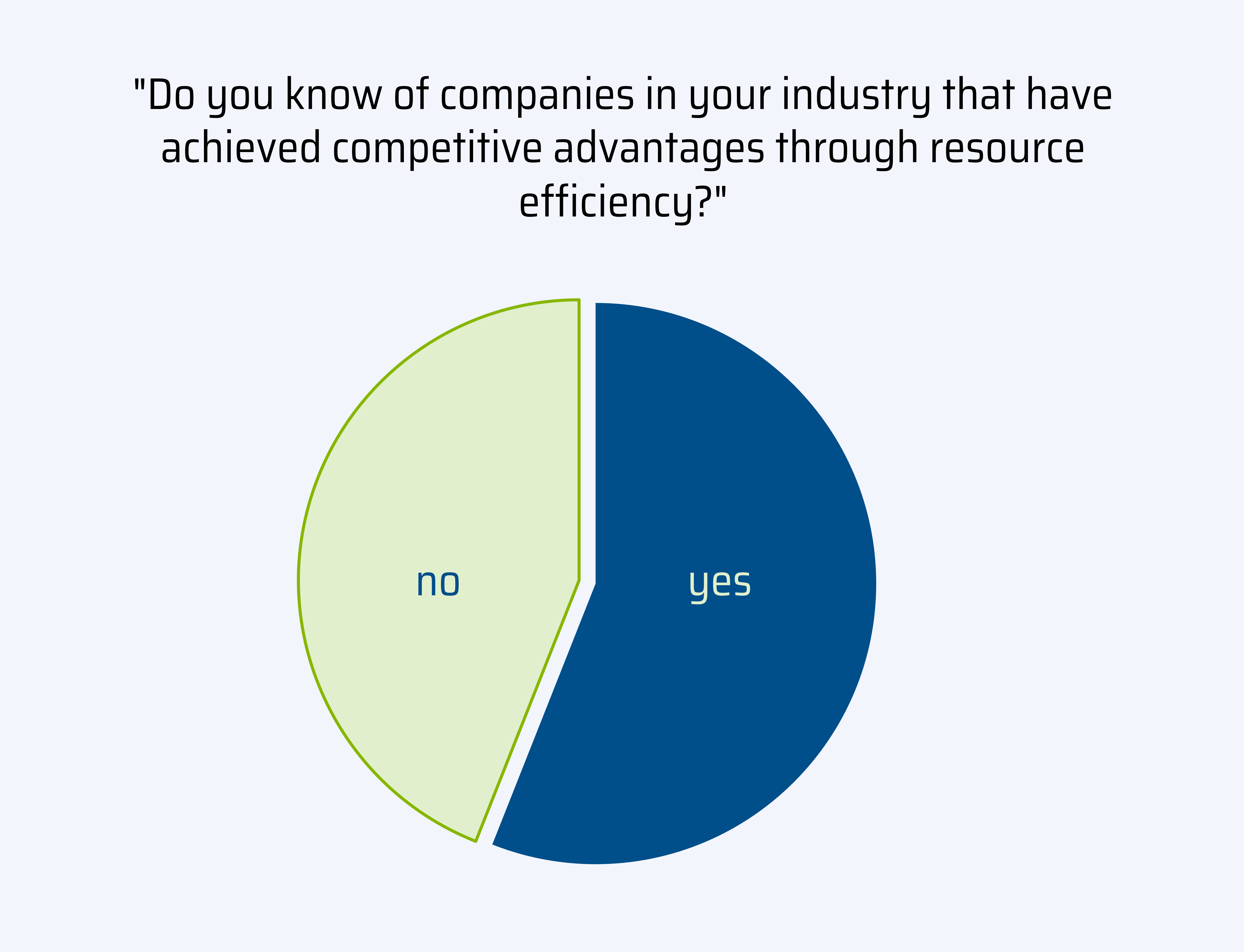

Even beyond this, companies can benefit from increasing their own resource efficiency.

An increase of operational resource efficiency also offers several economic advantages for companies. These include:

By operating in a resource-efficient manner, companies reduce their costs, make themselves less dependent on price fluctuations in the market and in return gain competitive advantages. In implementing resource efficiency, they also develop know-how, new processes and new technologies.

Another aspect that speaks for more resource efficiency in a company is the protection of the environment. The benefits for the environment are obvious, but the company itself also benefits. After all, customers are increasingly paying attention to the fact that goods are produced in an environmentally friendly manner. Resource efficiency therefore not only secures the future of the company, but also helps to preserve and (re)shape the future of an economy as well as the world.

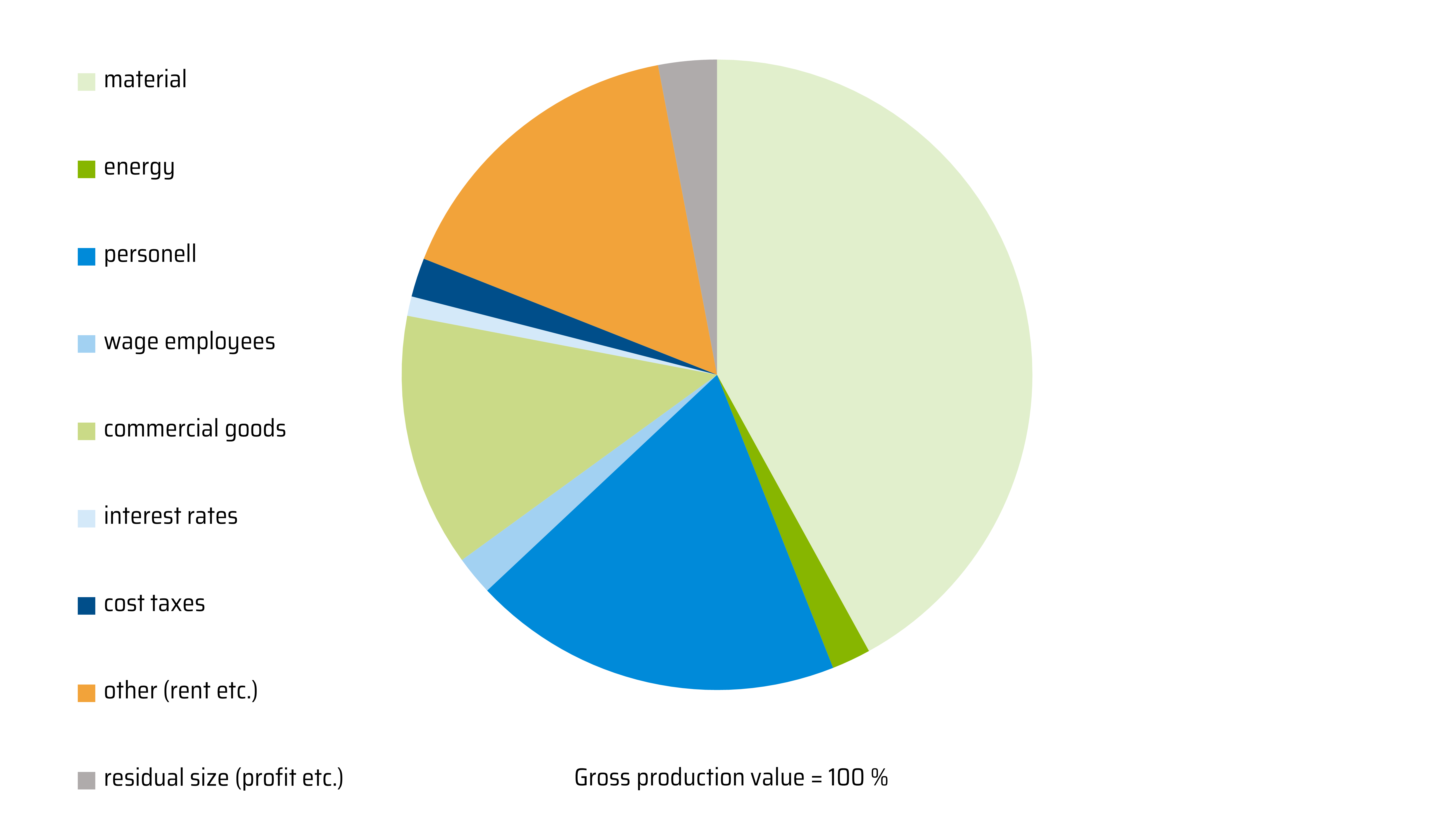

Resource efficiency is a proven method of sustainably strengthening a company's economic situation and competitiveness. Extensive experience from successfully implemented material and energy efficiency projects shows various ways to improve the economic situation of companies. © Statistisches Bundesamt (2019)

© Statistisches Bundesamt (2019)

According to the German Federal Statistical Office, in 2018 expenditure on materials accounted for the largest share of costs for companies in the German manufacturing sector, at around 42 percent. And this is no exception. For example, the share of material costs in the gross production value of small and medium-sized manufacturing companies has increased continuously over the past 30 years. This development is also reflected in the cost structure, compiled on the basis of data from the Federal Statistical Office of Germany.*

Cf. Statistisches Bundesamt (2020), Kostenstrukturstatistiken subject-matter series 4, vol. 4.3.

© Fotolia / Mark HulsIn order to successively expand future technologies and develop innovations, companies need raw materials such as high-tech metals (platinum, chromium, indium, etc.). Rising demand and the monopolistic positions of some mining regions can lead to price increases and subsequently to associated economic burdens for companies. In particular for new technology areas such as electromobility, the expansion of renewable energies and advancing digitisation, Germany as an industrial location requires technological raw materials such as lithium, which is required for the production of lithium-ion batteries, or heavy and light rare earths, which are needed for magnets in electric cars or for generators in wind turbines. For these raw materials in particular, demand is expected to be higher in the future than is currently being produced.

© Fotolia / Mark HulsIn order to successively expand future technologies and develop innovations, companies need raw materials such as high-tech metals (platinum, chromium, indium, etc.). Rising demand and the monopolistic positions of some mining regions can lead to price increases and subsequently to associated economic burdens for companies. In particular for new technology areas such as electromobility, the expansion of renewable energies and advancing digitisation, Germany as an industrial location requires technological raw materials such as lithium, which is required for the production of lithium-ion batteries, or heavy and light rare earths, which are needed for magnets in electric cars or for generators in wind turbines. For these raw materials in particular, demand is expected to be higher in the future than is currently being produced.*

Marscheider-Weidemann, F.; Langkau, S.; Hummen, T.; Erdmann, L.; Espinoza, L. T.; Angerer, G.; Marwede, M. and Benecke S. (2016): Rohstoffe für Zukunftstechnologien 2016, Berlin.

Strategies and measures to increase resource efficiency can be product- or process-related and thus influence various subareas in the company, such as product development, factory planning or production. Measures that affect the manufacturing environment - for example, procurement, improving operational logistics or the production infrastructure - are also included. Even if in some cases extensive investments have to be made initially, these can pay for themselves after a short time.

The acceptance and success of measures to increase resource efficiency also depend heavily on the extent to which employees in the company are involved in the processes.

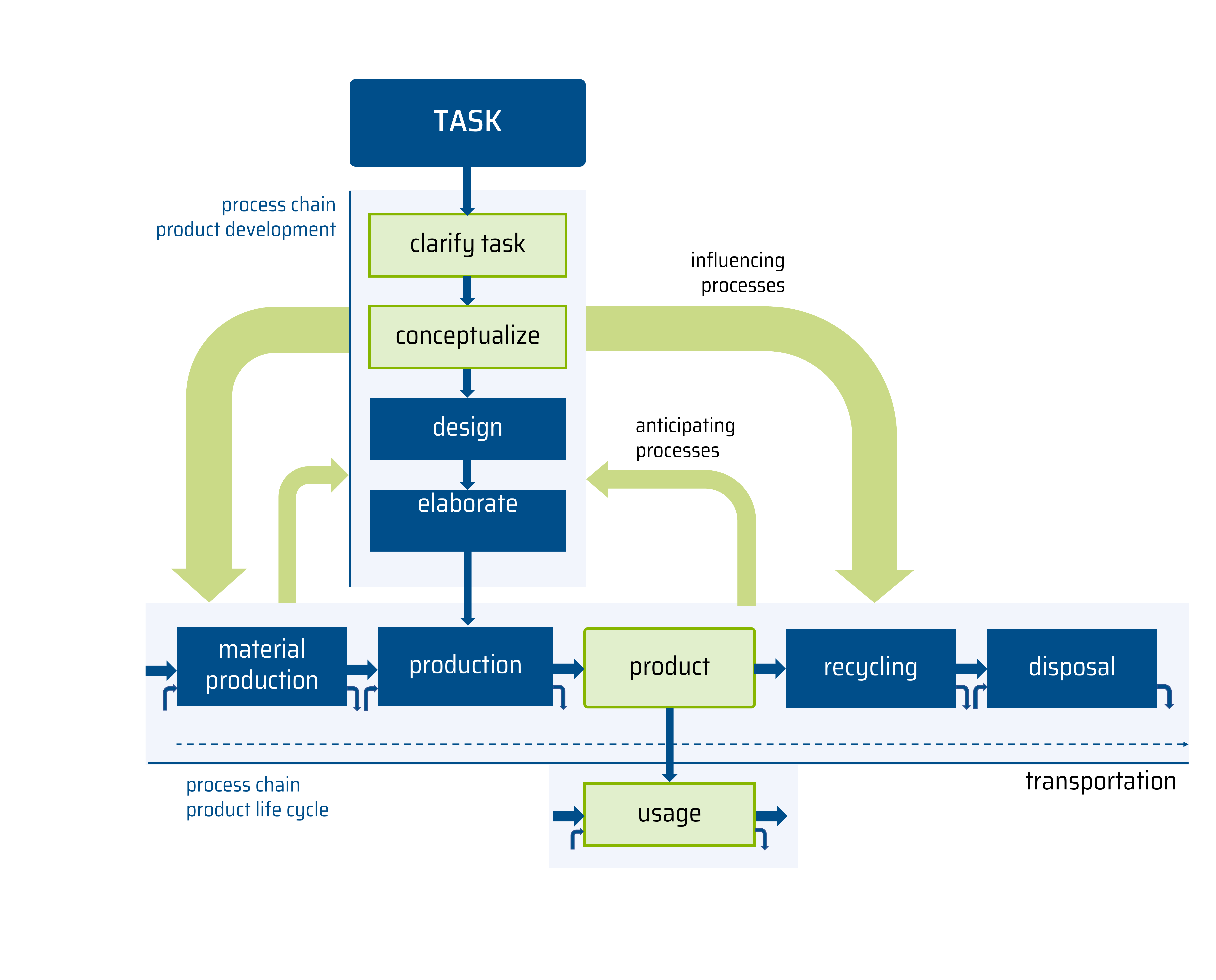

Product-related measures usually represent the most comprehensive approach to increasing resource efficiency. This is because most of the technical, economic and ecological key points are already defined in advance here. In addition to a large part of the costs, the use of resources over the entire product life cycle is defined in product development. For example, the selection of raw materials in the development process specifies the use of resources in the raw material extraction, manufacturing and use phases, and also influences the recycling and recovery process.

Although product-related measures generally have the greatest influence on resource efficiency, not every company has an influence on product design because product specifications are prescribed by the client or customers and are difficult to adapt. For these companies, therefore, measures to improve resource efficiency in the production processes within their own company boundaries play an essential role.

The following diagram illustrates this interplay between product development and product life cycle.

© VDI ZRE

© VDI ZRE

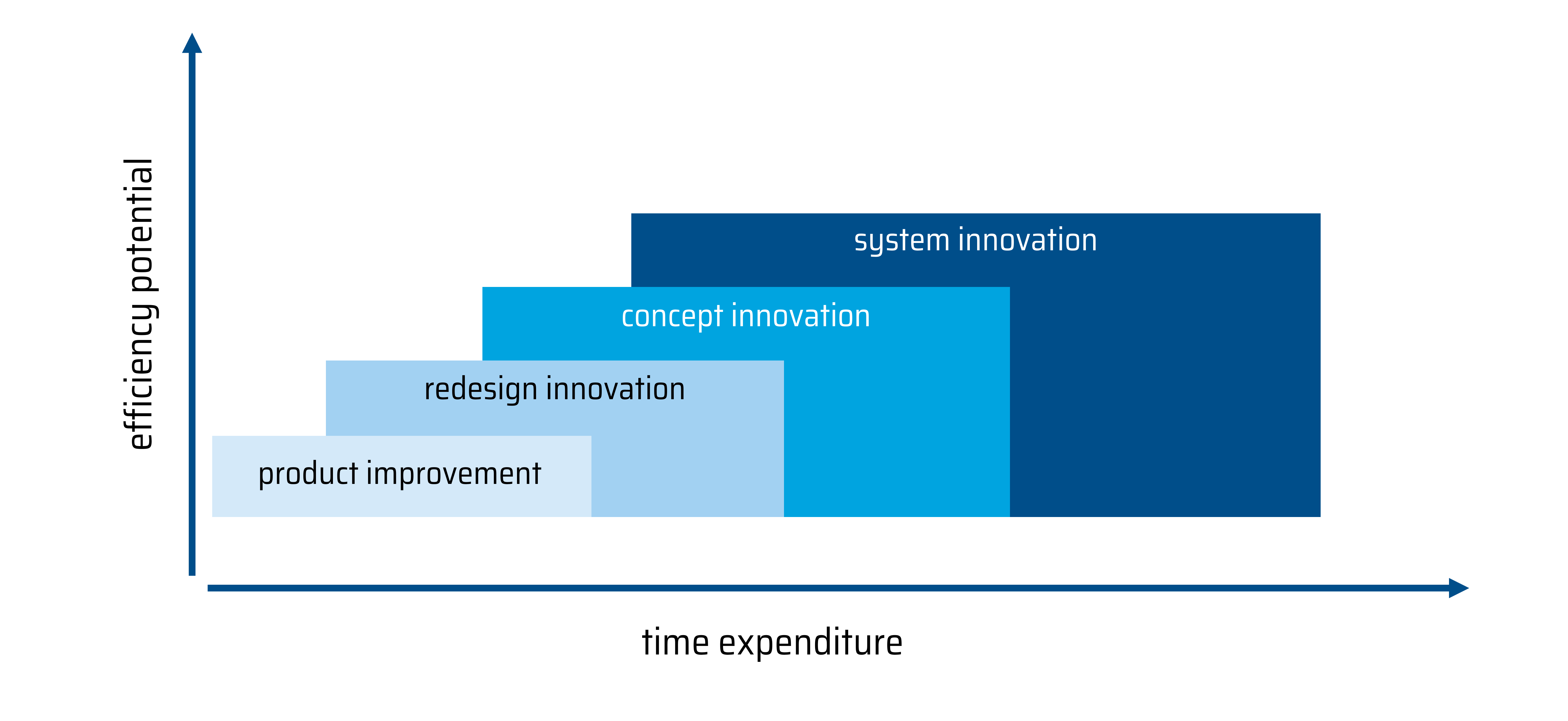

It is the level of the system that has a significant influence on the resource efficiency potentials that can be achieved. This is because the target group does not buy products, but benefits or functions. Therefore, the benefit must be seen as the starting point for significant efficiency improvements. A solution-neutral formulation of the benefit via the functional unit is an essential requirement.

© VDI ZRE (in Anlehnung an Brezet et al. [1997])

© VDI ZRE (in Anlehnung an Brezet et al. [1997])

Four innovation levels with different potential for increasing resource efficiency are distinguished. The innovation levels presuppose different intervention options and require widely varying expenditures and time frames with regard to their implementation.

According to the guideline VDI 4801 "Resource efficiency in small and medium-sized enterprises (SMEs)", the procedure for implementing RE measures is subdivided into the five superordinate steps:

Some of the steps are further subdivided into sub-steps. For example, in the important step of analysis, a distinction is made between rough and detailed analysis and between analysis of production and analysis of the life cycle. Steps 1 to 3 may need to be iterated through in order to select and then implement a suitable solution.

Based on different methods and tools for the individual steps, the tool Resource Efficiency Guide offers guidance and support for the successful implementation of operational resource efficiency measures.

Find out how you can reduce material losses caused by rework in production, for example, and lower your overall energy consumption. Once you have answered all the questions, the evaluation will show you possible efficiency potential in your company. In addition, you will be presented with measures, methods and tools that you can use to reduce resource consumption.

Continue to Resource CheckFind out how you can reduce material losses caused by rework in production, for example, and lower your overall energy consumption. Once you have answered all the questions, the evaluation will show you possible efficiency potential in your company. In addition, you will be presented with measures, methods and tools that you can use to reduce resource consumption.

Continue to Resource CheckGet in touch for further information or help regarding the topic of "Resource Efficiency".

Tel.: +49 (0)30 2759506-505

E-Mail: zre-industrie@vdi.de